Pet Plastic 100ml 500ml 1L 2L Bottle Making Maker Heating Blowing Extrusion Blow Molding Moulding Machine Blowing Blower

Description

Basic Info.

| Certification | CE, ISO9001:2008, QS |

| Capacity | 800bph to 9000bph Bottle Machine |

| Bottle Volume | 200ml-5000ml Bottle Blowing Machine |

| Controlled by | PLC (Mitsubishi) |

| Application | Beverage Bottle, Oil Bottle |

| Processing Material | Pet Preform,Plastic |

| Elctric | Siemens, Mitsubishi, etc |

| Composition | Plastic Bottle Making Machine |

| Certificate | CE, ISO, SGS |

| Transport Package | Wooden Case |

| Specification | 3.2m*1.8m*2.4m |

| Trademark | Proman |

| Origin | China |

| HS Code | 8422301090 |

| Production Capacity | 300machines/Year |

Product Description

Pet Plastic 100ml 500ml 1L 2L Bottle Making Maker Heating Blowing Extrusion Blow Molding Moulding Machine Blowing Blower

The PET bottle blowing machine plastic bottle machine is suitable for the production of 0.1-2.0L plastic containers and round and square bottles.

PM series pet stretch blow molding machine is the most stable two-step automatic stretch blow moulding machine.

It has various cavities and the maximum capacity of the products is 20L.

It can blow bottles in shapes: carbonated, mineral, pesticide, cosmetics, wide-mouth, hot filling, and other packing containers etc. which is made of plastic of crystalline type, such as PET and PP etc.

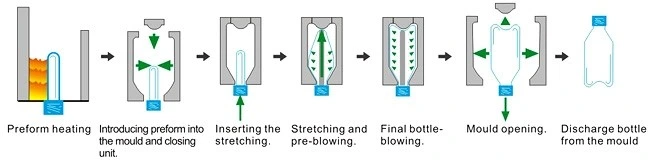

PET preform→Autoloader→Reheater →Molding→ Bottles

| Model | K4 | K6 | K8 | K12 | |

| Bottle type specification | Cavity | 4 | 6 | 8 | 12 |

| Max.volume | 2L | 2L | 2L | 0.75L | |

| Bottle mouth maximum overall diameter | 28-38mm | 28-38mm | 28-38mm | 28-38mm | |

| Bottle biggest diameter | 100mm | 100mm | 100mm | 100mm | |

| Bottle maximum height | 330mm | 330mm | 330mm | 330mm | |

| Capacity | Theory output | 6000-8500BPH | 9000-12000BPH | 14000BPH | 24000BPH |

| Power specification | Light tube quantity | 16pcs | 32pcs | 32pcs | 32pcs |

| Light tube power | 1.25KW | 1.25KW | 1.5KW | 1.75kw | |

| Maximum heating power | 20KW | 40kw | 48KW | 56kw | |

| All electric machine installation | 29KW | 49kw | 65KW | 71kw | |

| Actual consumption | 30%--60% | 30%--60% | 30%--60% | 30%--60% | |

| Air pressure specification | Work pressure | 5-6kg/cm2 | 5-6kg/cm2 | 5-6kg/cm2 | 5-6kg/cm2 |

| Blow bottle pressure | 25-45kg/cm2 | 25-45kg/cm2 | 25-45kg/cm2 | 25-45kg/cm2 | |

| Higher -pressure gas consumption | 6000Ltr/min | 8000Ltr/min | 12000Ltr/min | 24000Ltr/min | |

| Air pressure specification | Work pressure | 5-6 kg/cm2 | 5-6 kg/cm2 | 5-6 kg/cm2 | 5-6 kg/cm2 |

| Temperature range | 10ºC | 10ºC | 10ºC | 10ºC | |

| Consumption | 8000kcal/hr | 8000kcal/hr | 12000kcal/hr | 12000kcal/hr | |

| Forzen water flow | 88L/min | 120L/min | 150L/min | 220L/min | |

| Machine specification | Machine size | 3.6x1.6x1.9 | 4.8x1.8x1.9 | 5.8x1.6x1.9 | 7.6x1.6x1.9 |

| Machine weight | 4.3tons | 6.1tons | 7.5tons | 11.5tons | |

Component Display

1.How to tell us your enquiry? You can contact us by email, phone call, fax, Instant Messenger (Trademanager, WhatsApp, Skype) and let us know your requirement.

2.Where is your factory? Our Factory is located in Zhangjiagang City, it is very near to Shanghai and Wuxi (airplame and train both available). If you arrive at Shanghai or Wuxi, we can pick you up to visit our factory.

3. Do you have any technical supports with your blow molding Machine? Yes, We have a professional team of engineers who owned many installation, debug and training experiences abroad, are available to service machinery overseas.

4.What's your guarantee or the warranty of the quality if we buy your machines? We offer you high quality machines with 1 year guarantee and supply life-long technical support.We Warmly Welcome Customers All Over The World To Our Company If You Have Interests In Our Products. Please Contact Us If You Have Any Problems.

Prev: Pet Hair Grooming Blower for Large Dogs

Next: High Pressure 48V DC Brushless Blower with Medical Use

Our Contact